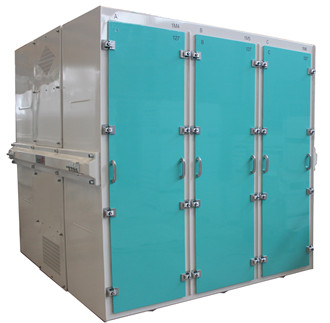

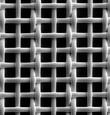

Flour milling is a process of grinding and separating, done by roller-mills, sifters and purifiers. Gezi offers a wide range of high-quality, sifting fabrics and bolting cloths for milling applications. Our flour bolting mesh line is carefully adapted to the special requirements of the flour milling industry and provides optimal sifting efficiency and maximum service life.

The synthetic fibers, such as polyamide (nylon), polyester, polyethylene and polypropylene are mostly selected for the meshes. They are suitable for the filtering, screening and straining in the field of foodstuffs industry, chemical industry, automobile industry and medical engineering. We can mainly supply you the meshes made by polyester and polyamide and plain-woven for light, normal and heavy duty by selecting different diameter of the monofilament. The filament can be doubled, non-crimped, half-crimped or double crimped. The meshes can be woven in plain, twill or Dutch, and will be bleached and set after weaving.

PA- GG PA- XXX PA- MF PA- Milling

1. PA- GG

Long life time

High efficiency

2. PA- XXX

Good abrasion resistance

.jpg)

At present, most of distinguish powder machine has switched to polyester material mesh, because it has much rough surface to slow down the flow speed of material..Polyester mesh is hardly influenced by material humidity change and climate conditions, and the sieve disc often keeps tight, so it has a good and lasting cleaning efficiency.

Keeps constant tension

Best sieving efficiency

Best possible durability combined with high sieving efficiency

And we have accessories for flour machine, such as canvas cloth, plastic clean piece.

6. Normal width of sieve mesh: 100cm, 115cm, 120cm, 136cm, 145cm, 158cm.

7. More details items, please kindly check that in our Terms& Service page.

Pre: 2020 Best Stainless Steel Filter Disc Strainer

Next: 20mm Nonwoven Micron Filter Cloth Polyester / Cotton Wadding for Quilts

MACROKUN has established long-term and stable cooperative relations with many transportation companies such as China Post, DHL, FEDEX, USPS, UPS, etc. Of course, MACROKUN can also provide air and sea transportation. The powerful logistics system enables all MACROKUN'S Printing Mesh, Filter Mesh and Filter Bags and so on to be easily and efficiently transported to any place. For quotes and inquiries, please email our sales team.